Reproduced

from: http://gizmodo.com/5613794/what-is-exactly-a-doctorate

Ever wondered

what getting a doctorate really means? Matt Might, professor of Computer

Science at the University of Utah, explains it perfectly in this graphic

presentation that starts with a simple circle:

Every fall, I

explain to a fresh batch of Ph.D. students what a Ph.D. is.

It's hard to

describe it in words.

So, I use

pictures.

Read below

for the illustrated guide to a Ph.D.

Imagine a

circle that contains all of human knowledge:

SEXPAND

By the time

you finish elementary school, you know a little:

SEXPAND

By the time

you finish high school, you know a bit more:

SEXPAND

With a

bachelor's degree, you gain a specialty:

SEXPAND

A master's

degree deepens that specialty:

SEXPAND

Reading

research papers takes you to the edge of human knowledge:

SEXPAND

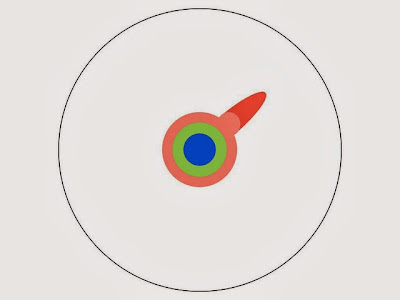

Once you're

at the boundary, you focus:

SEXPAND

You push at

the boundary for a few years:

SEXPAND

Until one

day, the boundary gives way:

SEXPAND

And, that

dent you've made is called a Ph.D.:

SEXPAND

Of course,

the world looks different to you now:

SEXPAND

So, don't

forget the bigger picture:

SEXPAND

Matt Might is a professor of

Computer Science at the University of Utah. He finished his dent at Georgia

Tech in 2007, and now enjoys advising his own Ph.D. students on how to make

theirs. He tweets from @mattmight and

blogs atblog.might.net.